MRF - Lab or R&D Furnaces

Top loading Lab Furnace

- 2500°C (4532 °F) in Inert gas, vacuum, Hydrogen or Ammonia

- Operating pressure: 1×10-7 Torr (mbar) to 2 P.S.I.G. (0.14 bar)

- Excellent temperature uniformity

- Many hot zone sizes and materials available

- HMI control system with Data-acquisition

- Ergonomic space saving design

- TC and pyrometer temperature control

- Turbo pumping system

- Wet Hydrogen system available

- Top loading with compact footprint

3000C Tube Furnace

- 3000C maximum temperature

- Economical furnace with multiple uses, can be operated vertical or horizontal

- Muffle tubes for oxidation atmospheres available.

Multi-application Front Loading Furnace

- Front loading multi-application furnace with Ultra-High vacuum pumping system.

- 2000C 4 "x 8" metallic or graphite hot zone.

- large array of options such as Hot pressing, Quenching, Crystal growing

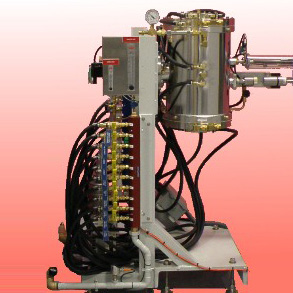

5 or 10 Ton Hot press

- Up to 2300 °C (4172 °F) in gas or vacuum, 2600 °C (4712 °F) in batch configuration

- 5 Ton (44.5 kN) or 10 Ton (88.9 kN) load frame and hydraulic press system

- Travel 4” (102 mm) with 0.001” (0.02 mm) control increments

- Pressure control with 1 lb (4 N) force increments

- Excellent temperature uniformity

- Graphite, Ceramic or Metallic hot zone

- Classic instrument control or a PC with HMI with user-friendly interface

- 4″ diameter x 8″ high (101 mm x 203 mm) hot zone size

Hydrogen Bell Jar

- 2000°C Maximum (3632 F) without molybdenum retort

- 1500°C (2732 F) with molybdenum retort

- Hot zone size of 8″ diameter x 10″ high (203 mm x 254 mm)

- Automated lift and clamp mechanism for bell jar chamber

- Hydrogen operation with integrated safeties

- Retort allows removal of volatile substances while improving thermal uniformity

- Space-saving design

Air, Vacuum and Gas Furnace

- Interchangeable 1650C Ceramic zone for operation in air, or a 2000C graphite zone for operation in inert gas or vacuum.

- Mounts in physical test frame, has two chamber access doors, turbo pumping system.