Conveyor Furnace

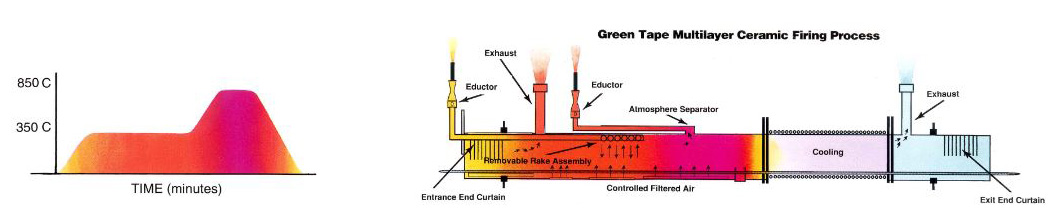

Green tape multilayer ceramic firing

- Low Temperature Cofired Ceramic tape(LTCC) is fired to form multilayer interconnects with integrated resistor systems, this is apically a thick film process with prolonged burn-out to accommodate the large amount of binder materials, Burn-out may be in-line or in a separate oven, A specialized exhaust afterburner is optionally available to post/ combust exhausting binder materials.

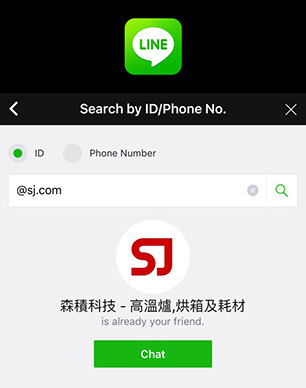

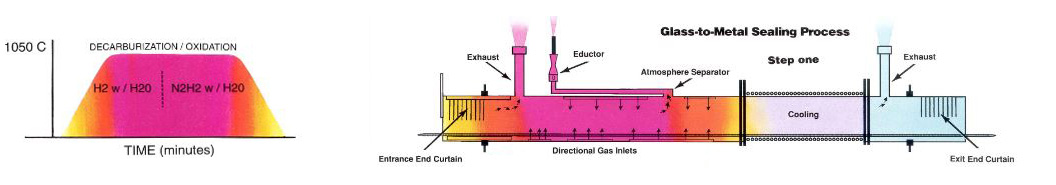

Glass-to metal seals

- Two types of glass-to-metal are prominent; seal of Kovar leadframes and feedthrough compression seals. In both cases it is necessary to grow a controlled oxide onto the metal surface to allow glass adherence. The seal may then be accomplished by melting the glass and cooling under controlled conditions. While this process may be achieved in a single furnace, the preferred method is to use tow furnaces.

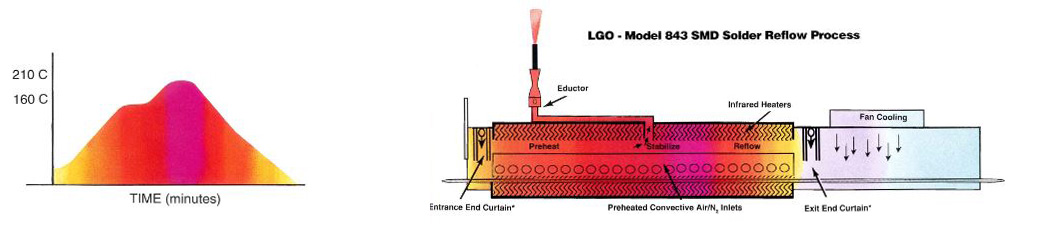

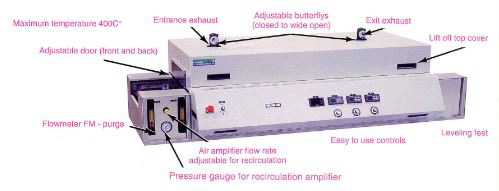

LGO-Model 843

Infrared furnaces and ovens

- Model 843 infrared systems offer higher operating temperatures and higher intensity infrared energy. They offer temperatures up to 1100C and accommodate “muffleless” atmosphere capabilities. They are the ideal choice for SMD reflow soldering, PolymerThick Film curing and Cermet Thick Film “Rapid Firing” applications.

Model 843 ATBL ( Inert Gas Model)

- 12”wide stainless belt

- Distributed top and bottom infrared heaters

- Hinged top

- Multifan, variable speed cooling

- Precision thermal and nitrogen atmosphere adjustment

- Convection recirculation system for thermal uniformity